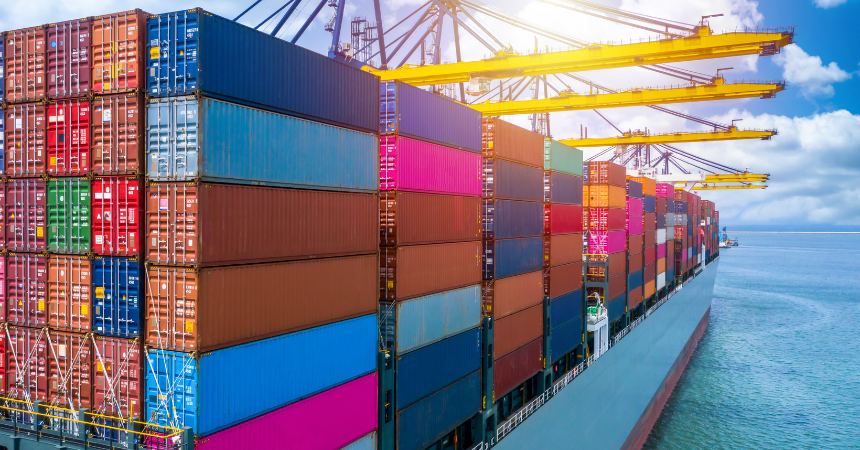

Steel shipping container homes have become increasingly popular in recent years, offering a unique blend of affordability, sustainability, and versatility. Crafted from repurposed shipping containers, these innovative dwellings have sparked the interest of homeowners seeking eco-friendly living solutions without compromising on style or comfort.

However, amidst the excitement surrounding container homes, one lingering concern often emerges: do container homes rust?

In this comprehensive guide, we'll delve into the truth behind this common misconception and provide detailed insights for those considering Quokka Container Cabins for their container home project needs in QLD or NSW.

Understanding the Factors: Dispelling the Myth of Container Rust

The perception that container homes inevitably rust stems from the materials used in their construction. Shipping containers are typically made from corten steel, a weather-resistant alloy designed to withstand the rigours of maritime transport. While corten steel is inherently resistant to corrosion, factors such as prolonged exposure to moisture, salt, and environmental elements can still contribute to rust formation over time which can have negative effects on the lifetime of the material.

However, it's essential to recognise that not all container homes are created equal. The extent to which rust affects a container home depends on various factors, including the quality of the container, the climate in which it's located, and the maintenance practices employed by the homeowner, possible reasons are listed below under '15 Tips for Shipping Container Upkeep'.

Prevention and Maintenance: Strategies for Rust Prevention

While rust may be a potential concern, it can be effectively mitigated through proactive prevention measures and regular maintenance.

Before repurposing a shipping container for residential use, thorough inspection is essential to identify any existing signs of rust or damage. Surface treatment, such as sandblasting or chemical rust removal, followed by the application of rust-inhibiting primer and marine-grade paint, can help protect the container against corrosion.

Additionally, implementing effective moisture control measures is crucial for preventing rust formation within the container. This may include proper insulation, ventilation systems, and moisture barriers to regulate humidity levels and minimise condensation. Regular inspections and maintenance routines should also be conducted to identify and address any signs of rust or deterioration promptly.

Quality Assurance with Quokka Container Cabins

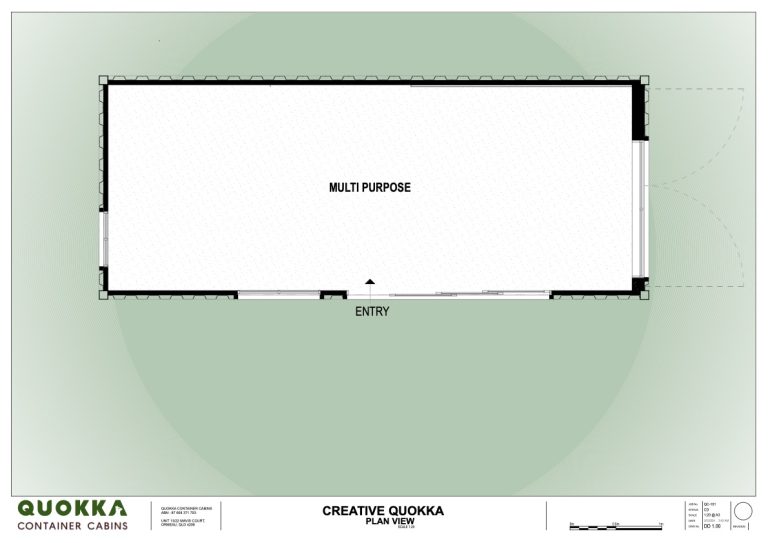

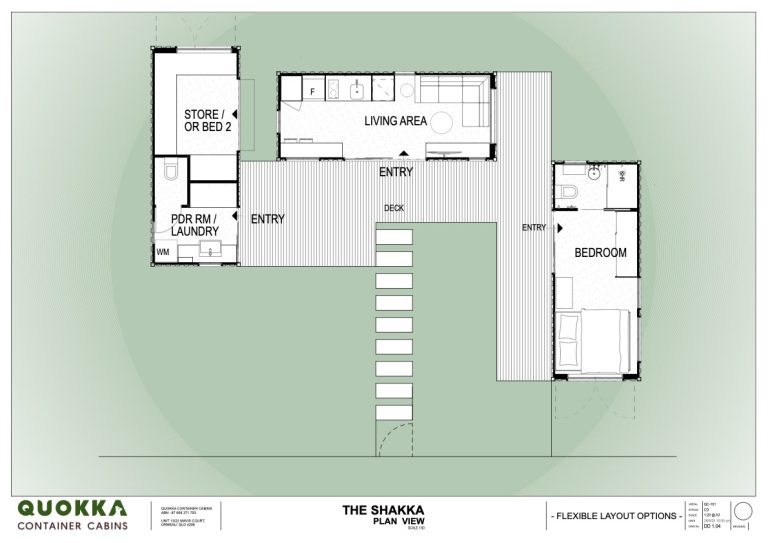

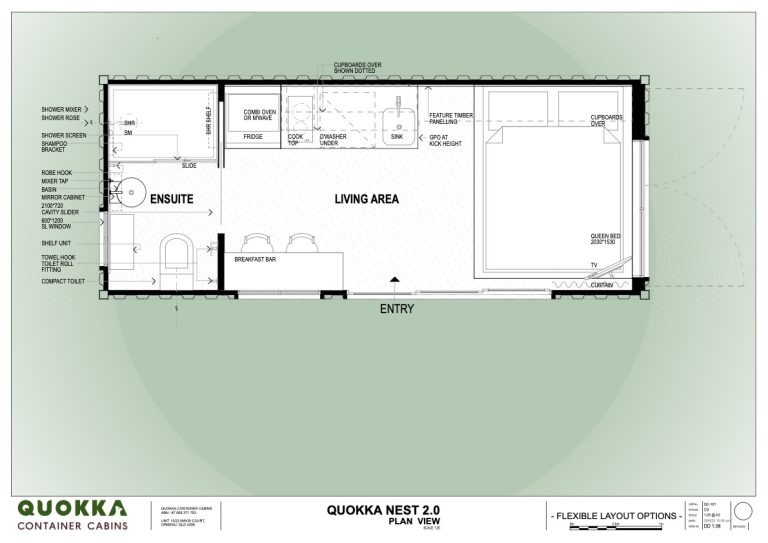

When choosing Quokka Container Cabins for your container home project, you can have confidence in the quality and durability of your investment. From basic shipping container homes to luxury shipping container modular homes

Each container cabin undergoes meticulous inspection and treatment to ensure compliance with the highest standards of structural integrity and corrosion resistance. With a focus on using premium materials and proven construction techniques, Quokka Container Cabins delivers container homes that are built to withstand the test of time and environmental challenges.

Moreover, Quokka Container Cabins offers comprehensive support throughout the entire process, from initial design consultation to final installation and beyond. With their expertise and dedication to customer satisfaction, homeowners can trust Quokka Container Cabins to deliver a container home that exceeds expectations and stands the test of time.

15 Tips for Shipping Container Upkeep

-

- Material Composition: Shipping containers, the building blocks of container homes, are primarily made of corten steel, which is resistant to corrosion due to its high tensile strength and protective oxide layer.

- Exposure to Elements: Prolonged exposure to moisture, humidity, salt, and environmental pollutants can compromise the protective oxide layer on the steel surface, leading to rust formation.

- Previous Use: Containers used for shipping have often endured harsh maritime conditions, increasing the likelihood of surface damage and corrosion.

- Container Condition: Older containers or those with visible signs of wear and tear, such as dents, scratches, or rust spots, may be more prone to rust.

- Welded Joints: Welded joints and seams, where multiple steel panels are connected, are vulnerable points where moisture can penetrate and initiate rusting.

- Improper Storage: Incorrect storage practices, such as leaving containers in direct contact with damp ground or stacking them without proper ventilation, can accelerate rust formation.

- Lack of Maintenance: Neglecting regular maintenance, including cleaning, inspecting, and repainting, can allow rust to spread and compromise the structural integrity of the container.

- Climate Factors: Regions with high humidity, frequent rainfall, or coastal proximity pose a higher risk of rust due to increased moisture levels in the air.

- Condensation: Temperature differentials between the interior and exterior of the container can lead to condensation buildup, creating a conducive environment for rust to develop on interior surfaces.

- Water Leakage: Leaks or gaps in the container's roof, doors, or windows can allow water ingress, promoting rust formation on interior surfaces and structural components.

- Chemical Exposure: Exposure to corrosive chemicals, pollutants, or industrial emissions can accelerate the corrosion process, particularly in urban or industrial areas.

- Vegetation Accumulation: Overgrown vegetation or debris resting against the container exterior can trap moisture and promote rusting, especially in humid climates.

- Foundation Contact: Direct contact with a concrete foundation or moist soil can facilitate rusting along the container's bottom edges, where moisture tends to accumulate.

- Transportation Damage: During transportation or handling, containers may sustain surface scratches, abrasions, or impact damage, compromising the protective coating and exposing underlying steel to rust.

- Inadequate Coatings: Inadequate or deteriorating paint coatings on the container surface can fail to provide adequate protection against moisture and corrosion, accelerating rust formation.

Making an Informed Decision

While the concern about rust in container homes is valid, it is not insurmountable. By understanding the factors contributing to rust formation and implementing proactive prevention measures, homeowners can enjoy the benefits of container living without compromising on durability or aesthetics.

With Quokka Container Cabins, residents of QLD and NSW can embark on their container home journey with peace of mind, knowing that they are investing in a sustainable, rust-resistant housing solution backed by quality craftsmanship and expertise. So, if you're considering a container home for your property, rest assured that rust is not a barrier when you choose Quokka Container Cabins.

With careful planning, adherence to regulations, and the right expertise, you can transform a shipping container into a compact, efficient, and fully functional space that meets your specific needs. If you wish to know more about our prefab shipping container cabins, or more about our shipping container floor plans don't hesitate to contact the professionals at Quokka and get informed advice from professionals.